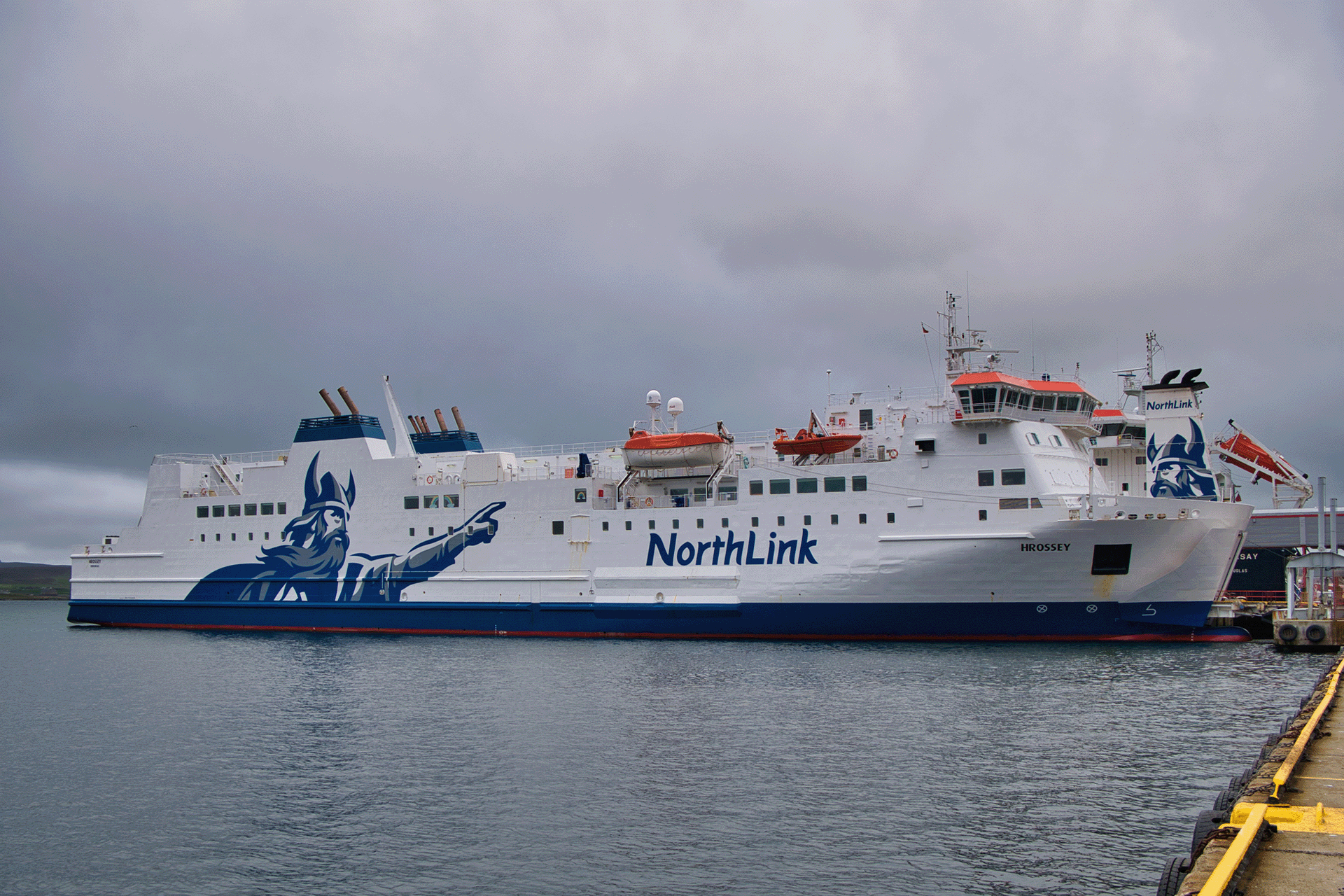

Northlink

The SeaKing Group, in collaboration with Schneider Electrics, has completed the UK’s first large ship-to-shore commercial connection installation in Stromness. This innovative project, involving the MV Hamnavoe operated by NorthLink Ferries, is a crucial component of a green power initiative to reduce emissions during the vessel’s port stays.

Summary of Works

Project Overview

Project Background:

Initiated by the Cold Ironing standard IEC 80005-3 and low voltage shore requirements, the project aimed to establish a shore power connection for MV Hamnavoe, significantly reducing emissions while in port. SeaKing’s selection for this project was based on their proven expertise in marine and land-based electrical projects.

Challenges:

The MV Hamnavoe operates in the challenging maritime environment of the Orkneys, navigating heavy seas and adverse weather conditions. The installation works had to be carefully phased to avoid disrupting ferry operations and maintain safety standards.

Project Background:

Initiated by the Cold Ironing standard IEC 80005-3 and low voltage shore requirements, the project aimed to establish a shore power connection for MV Hamnavoe, significantly reducing emissions while in port. SeaKing’s selection for this project was based on their proven expertise in marine and land-based electrical projects.

Project Phases

1st Phase (December 2018 – March 2019):

Manufacture of an extension to the switchboard and a new shore power connection panel.

Complete factory acceptance tests (FAT) to ensure the reliability and functionality of the newly manufactured components.

3rd Phase (December 2019):

SeaKing personnel sailed with the vessel to Stromness.

Commenced installation work during the day while the vessel was in port overnight.

Set up the manual operation aspect of the new ship installation, preparing for potential use during the forthcoming dry-dock period.

2nd Phase (July 2019):

Installation of onboard cable tray, penetrations, and cabling.

Extension to the main switchboard and establishing cables and containment from the engine control room (ECR) to six decks aft.

Construction of a new equipment house on the vessel to house the IP56-rated 415V shore power panel and auxiliary power supplies.

Conclusion:

The successful completion of the MV Hamnavoe ship-to-shore connection project marks a significant milestone in maritime electrification. SeaKing’s expertise, collaborative approach, and commitment to safety have contributed to implementing a cutting-edge solution that aligns with environmental standards and advances the industry’s commitment to green power initiatives. This project sets a precedent for future shore power installations, showcasing the SeaKing Group’s leadership in complex marine electrical engineering.