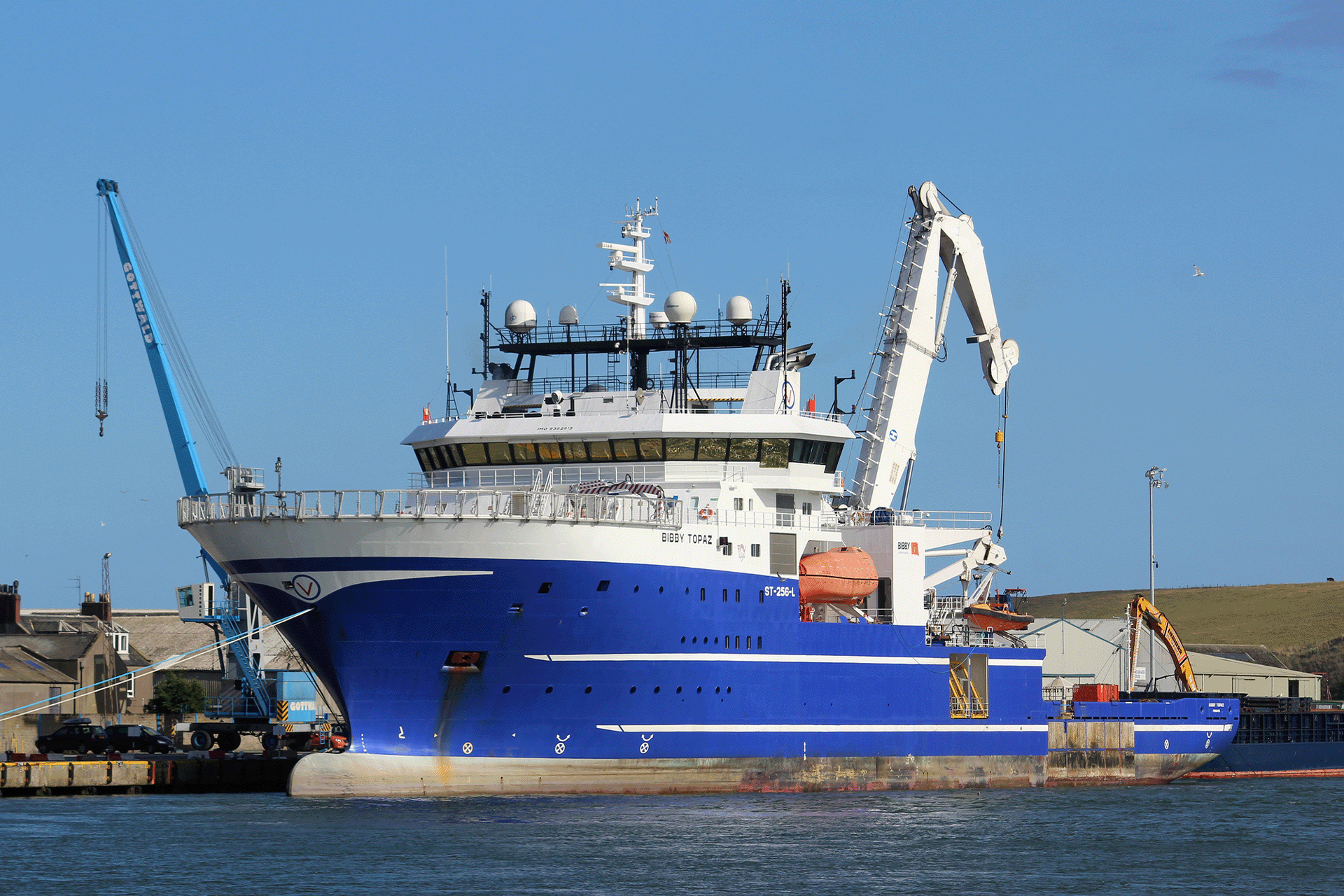

Bibby Sapphire

Undertaking on transforming the North Sea dive support vessel, ‘Bibby Sapphire,’

The SeaKing Group orchestrated a series of modifications during a pivotal dry docking at Cammell Laird’s shipyard in Merseyside.

Summary of Works

Project Scope and Modifications

Emergency Power Generator Installation:

Seamlessly integrated an emergency power generator to enhance onboard power resilience.

Ensured uninterrupted operations, critical for dive support functions.

Decompression Chamber Cable Penetrators:

Renewed all five decompression chamber cable penetrators to guarantee robust and reliable connectivity.

Enhancements focused on safety and communication integrity during underwater operations.

Hot Water and HERS Control System Modifications:

Tailored modifications to the hot water and HERS control system for improved efficiency.

Precision adjustments to enhance environmental controls crucial for diver safety.

Engine Start Panel and Clump Winch Improvements:

Implemented upgrades to the engine start panel for streamlined and reliable operations.

Enhanced the clump winch functionality, contributing to overall vessel performance.

External Deck Lighting Enhancements:

Improved exterior deck lighting for enhanced visibility and safety during night operations. Implementation of state-of-the-art lighting solutions for optimal operational conditions.

Technical Excellence and Precision:

The SeaKing Group’s commitment to technical excellence shone through in every modification. Adherence to maritime regulations and safety standards in all aspects of the project.

Dry Docking Duration:

Completed within the designated dry-docking period, showcasing efficiency and meticulous project management.

Outcome:

The Bibby Sapphire project represents The SeaKing Group’s ability to elevate dive support vessels to new heights. Our commitment to precision and safety ensures that maritime operations in the North Sea can rely on enhanced capabilities for the long haul.